Inflatables

Vorticity leads the design and testing of novel inflatable architectures, including aerodynamic decelerators and airbags for planetary landers. Vorticity partners with advanced textile manufacturers and inflation system providers to develop inflatable devices for extreme environments, including supersonic flight on Earth, and Mars entry, descent, and landing missions.

// KEY CAPABILITIES

Inflatable device design, stress analyses and drawing production

Finite Element Analysis (FEA) and Fluid–Structure Interaction (FSI) of inflatables, using LS-DYNA

Advanced textile material modelling

Inflatable structure stress, strain, and thermal analyses

Material and joint qualification testing

High-temperature flexible thermal protection systems

// KEY CASE STUDY - AIRBAG OPTIONS FOR MARS

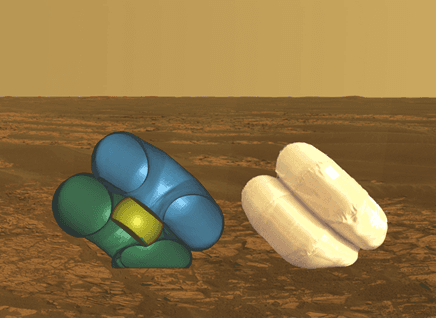

Vorticity supported early concept studies for the ExoMars landing system, which explored the use of airbags to cushion final impact on the Martian surface. Vorticity worked together with AeroSekur and CIRA to design, analyse and prototype two types of inflatable impact attenuation system.

The first was a conventional sealed airbag. This gradually disperses the impact energy through several bounces on the surface, before coming to rest and allowing the payload to deploy. The second was a novel vented airbag, which vents the compressed gas at a carefully timed point during initial impact, dispersing the impact energy without any rebounds.

Vorticity supported design, hardware manufacture and breadboard testing under Earth ambient pressure. The test data validated Vorticity’s analytical models and showed the potential benefits of vented airbags for planetary landing applications.

The videos above show unvented (left) and vented (right) inflatable systems being tested on a simulated Mars surface.

// KEY CASE STUDY - MERCURY LANDER INFLATABLES

Vorticity performed a concept study for an airbag landing system for the Bepi Columbo mission to Mercury. Although the final lander did not incorporate an airbag system, the concept was demonstrated to be entirely feasible.

// KEY CASE STUDY - FLEXIBLE TPS

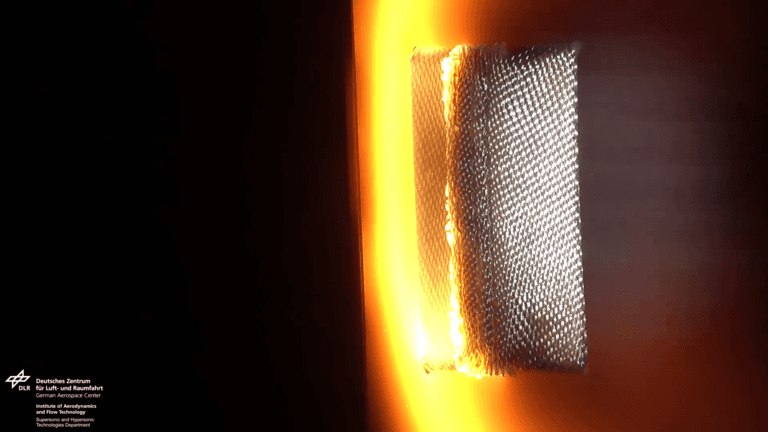

Flexible thermal protection systems (TPS) are essential components of launchers and deployable/inflatable entry systems. Wherever a deployable structure or inflatable membrane experiences significant thermal heating, flexible TPS is needed.

Vorticity has developed European-leading flexible TPS knowledge and design capability across several ESA research studies. We have particular experience of applying this knowledge to atmospheric entry and aerocapture mission design. Vorticity leads on flexible TPS requirements definition, system engineering, mechanical design, breadboarding, manufacture and qualification.

Vorticity also has well-established links with the European test facilities needed to flexible TPS ground testing and qualification.

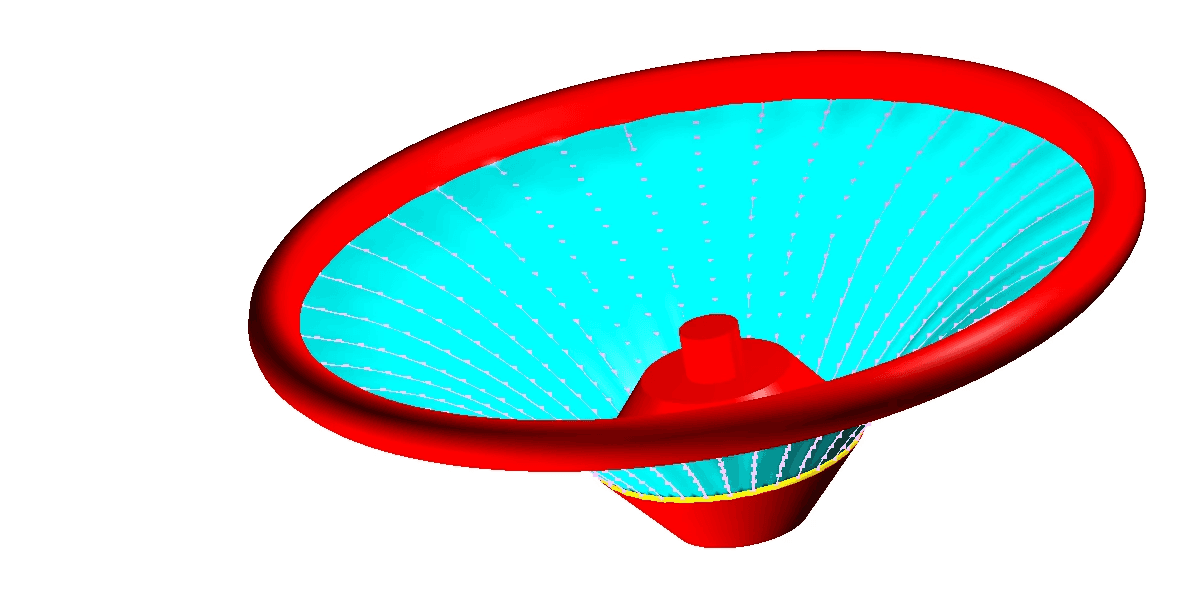

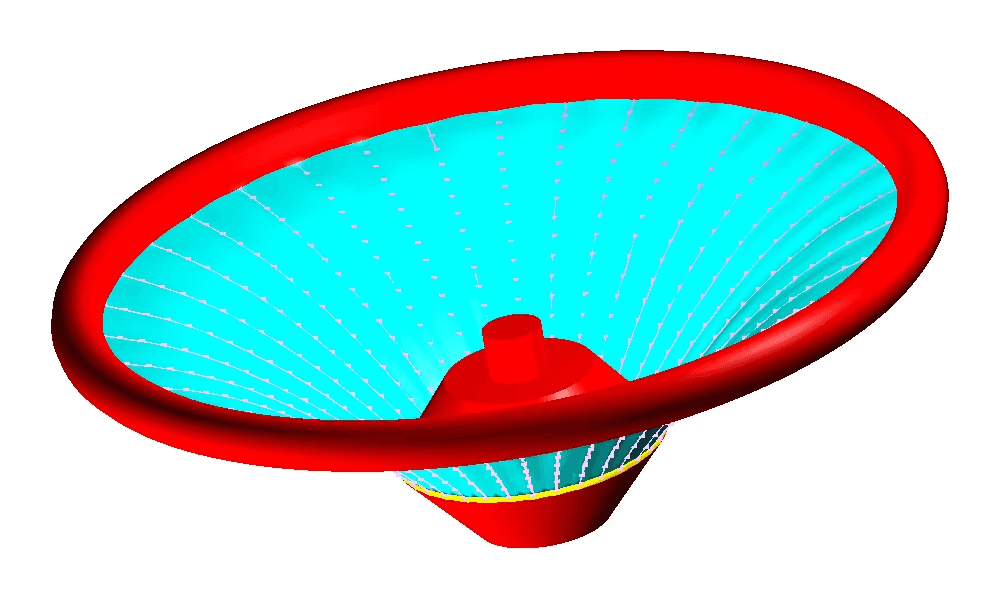

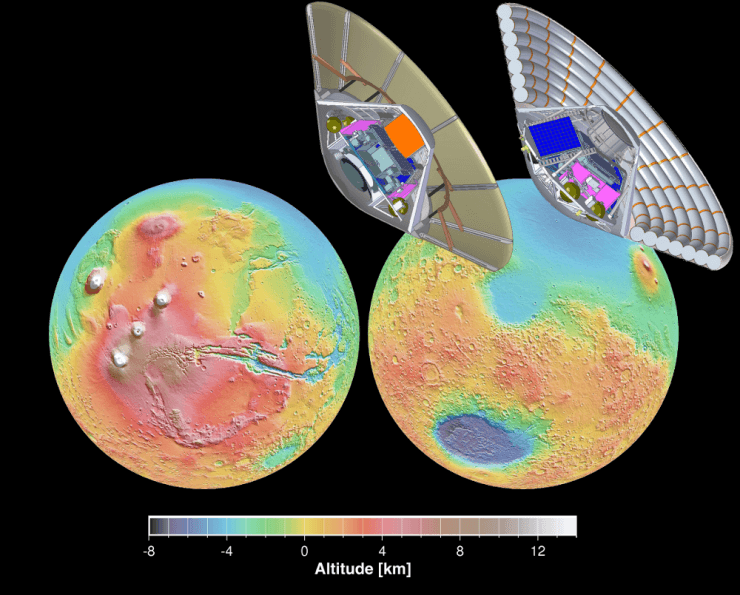

// KEY CASE STUDY - HYPERCONE SYSTEM STUDY FOR NASA JOHNSON

In this study, Vorticity supported NASA and Vertigo Inc to assess the potential of a Hypercone decelerator for landing high masses on Mars. The Hypercone is an aerodynamic decelerator designed to provide deceleration and stabilization from Mach 4 to subsonic conditions. Structural rigidity is provided by an outer inflated torus, which is connected to the payload by a drag-generating thin fabric surface. This assembly is fully flexible and can be packed into a small volume, like a parachute.

Vorticity were responsible for system analysis, trade studies and design. Inflation simulations, CFD prediction of aerodynamic performance, structural analysis, mass optimisation and trajectory analyses were all completed.