European Parachute Extraction Rig Study

Study on a new European test facility for dynamic parachute extraction testing

As part of a project funded by the European Space Agency (ESA), Vorticity conducted a study on a new European test facility for dynamic parachute extraction testing.

When parachutes are deployed, the parachute material is extracted from the deployment bag at high speed. Interaction with the parachute bag during deployment can cause damage, which will propagate and cause parachute failure during inflation. After a parachute has failed during inflation, it is impossible to determine whether the initial damage was caused during deployment or inflation. A facility that can replicate parachute extraction alone is therefore an invaluable tool for testing parachute deployment.

In a dynamic extraction test, a packed parachute is extracted from its deployment bag by a dedicated ground test rig, at accelerations and speeds matching flight conditions. These tests help identify any extraction failure modes in new parachute system designs, before more expensive and time-intensive drop tests. The parachute design, packing method and extraction speed can then be modified to mitigate potential failures. Subsequent extraction and drop tests are used to demonstrate the effectiveness of these improvements.

ExoMars parachute extraction in slow motion (learn more)

During the ESA ExoMars 2022 parachute system development, several dynamic extraction tests were conducted to investigate and address extraction issues observed during drop tests. All extraction testing was done at NASA JPL’s rigging test bed, as no comparable facility exists in Europe. To address this missing capability, a new European parachute dynamic extraction test facility has been designed.

The proposed new test facility allows packed parachutes to be extracted at flight-representative accelerations and speeds. Deployment acceleration and velocity are measured using IMUs and camera photogrammetry, while high-speed cameras record the dynamic behaviour from multiple angles. The extracted parachutes are then inspected for damage. The cause of any issues can be determined from the synchronised video and IMU data.

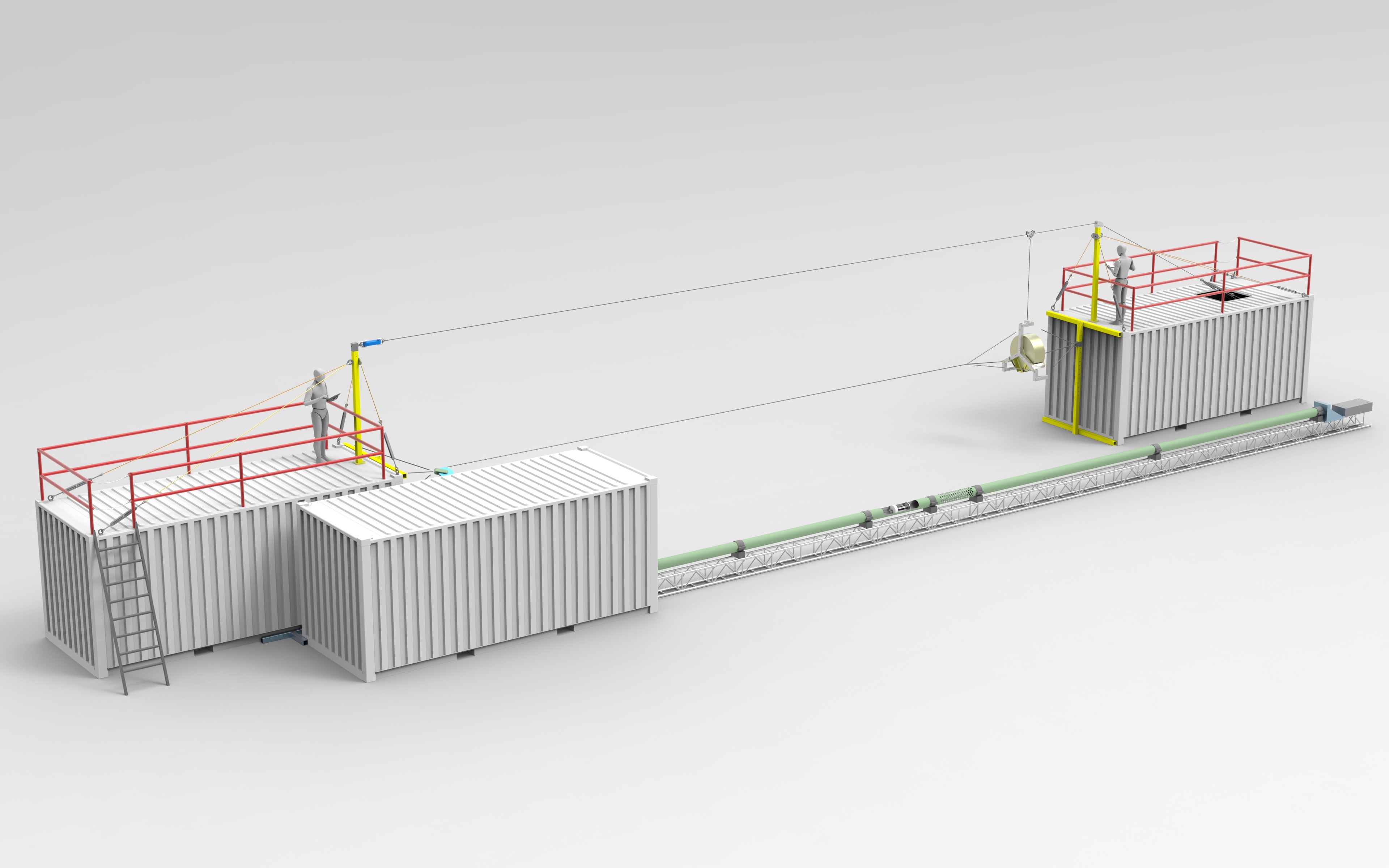

In its first configuration, this facility replicates parachute deployments that use pilot parachutes. The parachute pack is mounted on a trolley suspended from a guidewire. The trolley is attached to a piston by a pull line. The piston, propelled by pressurised air along a long horizontal pipe, moves the trolley along the test track and extracts the parachute. A braking net stops the trolley motion after the parachute is extracted. The facility can achieve bag strip velocities up to 80 m/s with an accuracy of ±2 m/s for a parachute system mass of 65 kg; and bag strip velocities up to 60 m/s for a parachute system mass of 140 kg. It accommodates extracted lengths up to 75 m.

Extraction rig system view

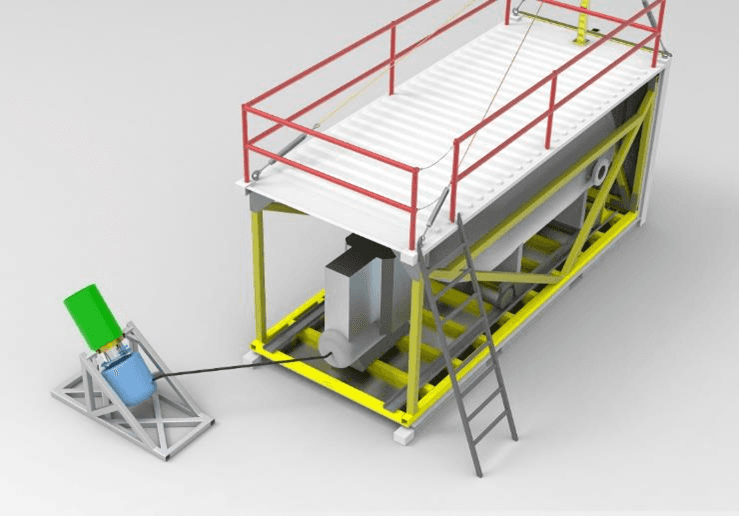

In a second configuration, pyrotechnic mortar deployments are replicated. An air mortar, consisting of a high-pressure air tank, pressure-sensitive burst disk and mortar tube, provides a high initial acceleration. The parachute pack is fired freely out of the mortar tube along the test track at a low elevation, deploying the suspension lines and canopy. The facility can match muzzle exit velocities up to 45 m/s. It accommodates parachute system masses up to 40 kg and deployment bag diameters up to 0.4 m.

Air mortar test facility concept

The facility is portable, constructed from three modified 20 ft (6 m long) shipping containers. The containers serve both as the structural frame for the test rig and as transport modules for its components. This design enables the test rig to be transported, assembled and operated at any suitable outdoor location in Europe or beyond. The project’s next steps involve completing construction and preparing the new facility for operational use, bringing an essential parachute testing capability to Europe for the first time.